Most manufacturing enterprises opt for machine vision technology or fixed-mount barcode readers to automatically capture barcode information. For instance, automotive battery manufacturers typically utilize fixed-mount barcode readers to automatically scan battery module information, thereby establishing battery-to-vehicle binding relationships. This data is then uploaded to the MES system for comprehensive traceability.

Achieve code scanning and information binding enabling data upload to the MES system for traceability

Barcode Reading Challenges:

1. Battery module sets are exceptionally large, demanding high-resolution clarity and reading accuracy across wide fields of view.

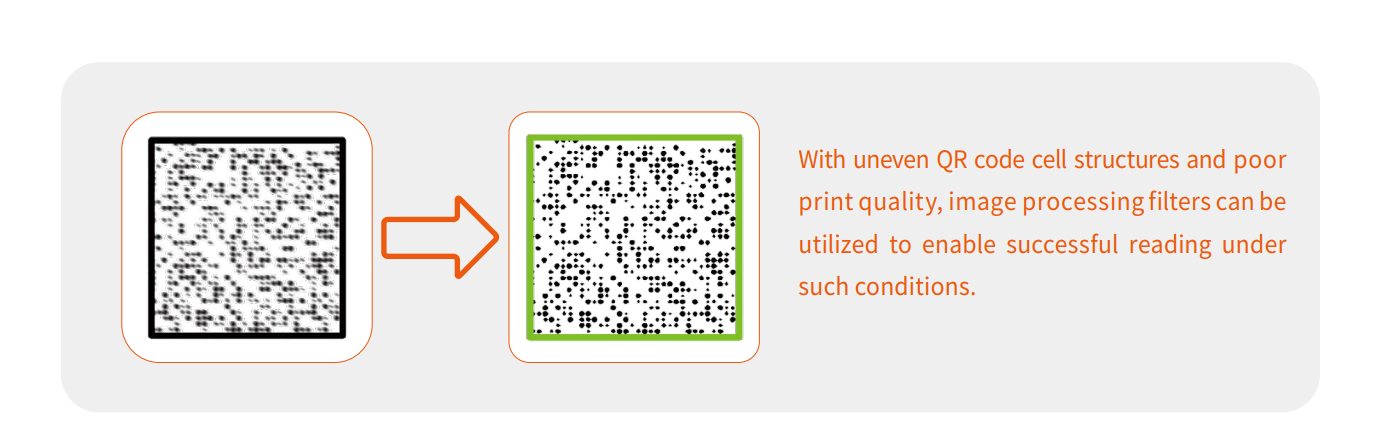

2. The spray-marking method used for QR codes results in irregular code cell structures, significantly increasing recognition difficulty.

Solutions:

1.To address reading accuracy requirements in large field-of-view applications, either high-pixel code readers can be deployed or multiple networked R-3000 series readers can be configured to achieve wide-area scanning - the latter proving more cost-effective

2.For uating the quality grade of barcode/QR code imprints, Evoc Reader can display reading scores, allowing optimization of marking quality based on these metrics. The R-3000 series code readers are commonly deployed in such production scenarios using networking functionality to meet large field-of-view requirements, featuring manual focus adjustment for cost-efficient performance. The R-7000 series offers expanded field coverage and accommodates high-density barcode applications, enabling wide-range reading of multiple product codes with auto-focus capability for simplified installation and debugging.

Solution Advantages:

1.The reading score displayed in Evoc Reader can be used to optimize the marking quality of barcodes and QR codes.

2.The R-7650 code reader achieves a 740mm×620mm field of view at 700mm mounting distance, coupled with a high-pixel camera to address the industry challenge of reading small codes in large viewing areas.