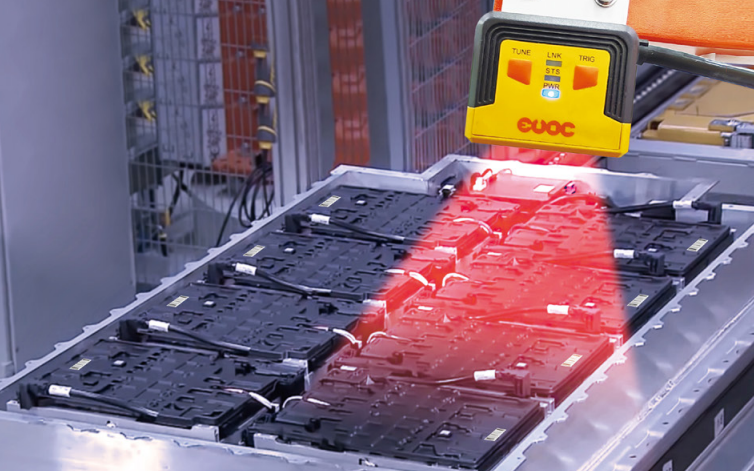

Most manufacturing enterprises opt for machine vision technology or fixed-mount barcode readers to automatically capture barcode information. For instance, automotive manufacturers typically utilize fixed-mount barcode readers to automatically read information beneath the varnish layer on motor stator flanges, thereby establishing stator-to-motor binding relationships. This data is then uploaded to the MES system to enable comprehensive traceability.

Achieve barcode scanning and information binding enabling data upload to the MES system and information tracking

Barcode Reading Challenges:

Barcode Reading Challenges:

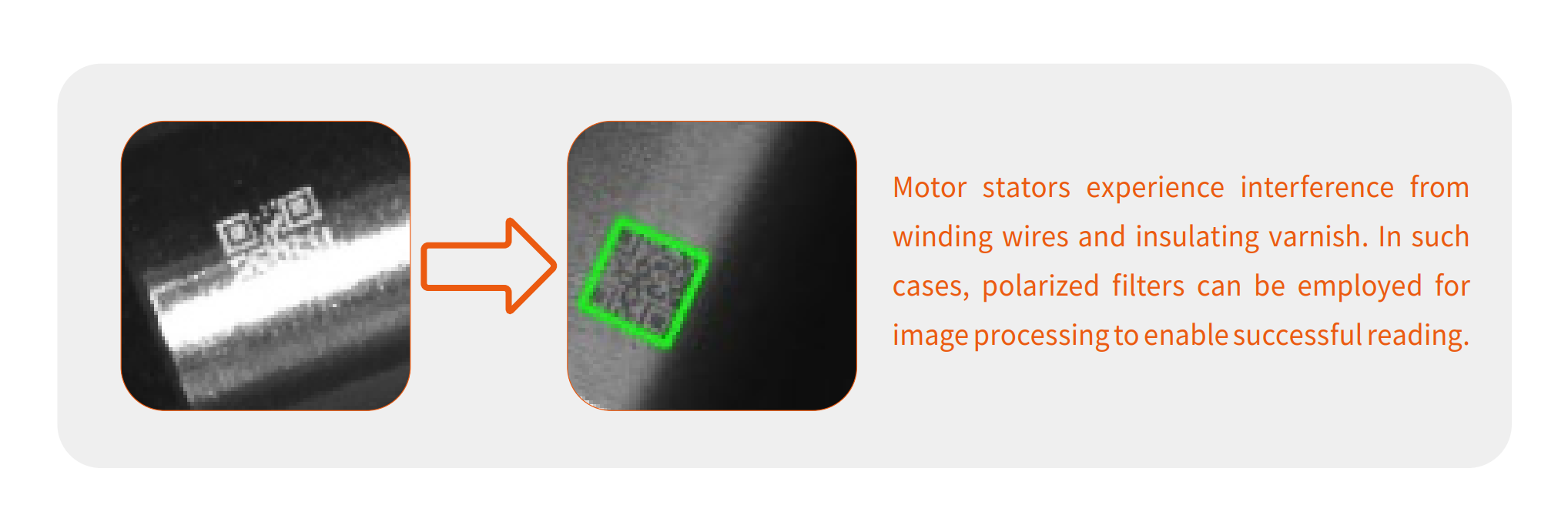

1. The stator is susceptible to interference from winding wires, increasing recognition difficulty.

2. Partial coating of insulating varnish on the barcode causes light halo effects, making identification challenging.

Solution Advantages:

1. Regarding the potential occlusion of barcodes by stator windings: if only partially covered, the intelligent AI decoding algorithm can handle it without reading difficulty.

2. For non-metallic surface glare affecting reader imaging (resulting in "unreadable codes"), polarized filters can be installed on the reader to effectively suppress reflections. The R-6000 series reader is commonly used in such production scenarios, featuring:

High resolution

Large field of view

Excellent high-speed small-code decoding

Multi-scenario applicability

Auto-focus support for simpler installation and debugging.