Most manufacturing enterprises opt for machine vision technology or fixed-mount barcode readers to automatically capture barcode information. For instance, automotive manufacturers typically use fixed-mount barcode readers to simultaneously scan QR codes on engine products and identify pallet barcode information, thereby binding products to their respective pallets. This data is then uploaded to the MES system for traceability purposes.

Achieve barcode scanning information binding and traceability upload

Barcode Reading Challenges:

Barcode Reading Challenges:

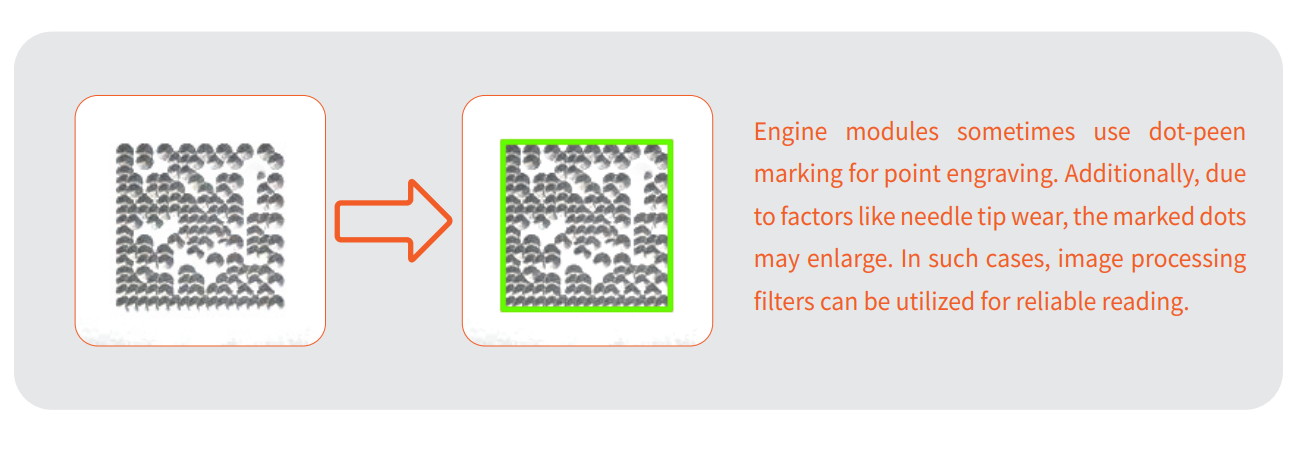

1. Dot-peen marked codes on engine modules increase recognition difficulty;

2. Time-dependent variations in dot-peen markings affect imprint consistency, leading to degraded code quality;

3. High demands on the code reader's field of view and depth of field;

4. Requires rapid QR code localization and reading in large field-of-view environments.

Solutions:

1. The main challenge in reading dot-peen markings lies in the similar color and low contrast between the code and background. This can be addressed by installing external lighting and adjusting the lighting angle to highlight the dot-peen QR codes. The R-8000 series code reader employs matrix-designed infrared lighting, allowing flexible adjustment of lighting modes through Evoc Reader software. Paired with a high-resolution camera, it delivers clearer imaging while ensuring fast and accurate reading performance under large field-of-view and deep depth-of-field conditions.

2.To ensure rapid QR code localization within large fields of view, the "Define Reading Area" function in Evoc Reader software can be utilized to guarantee quick code positioning and reading by the code reader.

Solution Advantages:

1.A single code reader is sufficient to cover large field-of-view applications.

2.The matrix lighting design provides superior uniformity, ensuring clearer imaging and enhanced reading accuracy.

3.Configuring the reading zone in Evoc Reader guarantees rapid code localization during actual production operations.