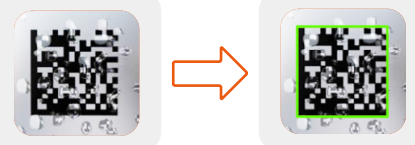

Currently, most enterprises opt for machine vision technology or fixed-mount barcode readers to automatically capture barcode information. Relying solely on manual handheld scanning would impose significant workload, forcing companies to incur high labor costs while being prone to errors. As shown in the right figure, automotive manufacturers typically use fixed-mount barcode readers to automatically scan QR codes on products for managing loading/unloading, station transitions, and inspections. This approach not only operates at high speed to greatly improve efficiency, but also reduces labor costs.

Achieve barcode reading/scanning requirements throughout automotive and auto parts manufacturing processes including casting machining inspection and assembly thereby enhancing production efficiency and reducing labor costs.

Barcode Reading Challenges:

1. Water droplets on crankshaft surfaces - varying droplet shapes cause reflective interference and potential barcode occlusion, impacting read reliability;

2. Curved-surface barcodes - introduce additional decoding complexity for standard readers;

3. Metallic substrate limitations - environmental light interference persists even with polarizing filters;

4. Harsh operating conditions - oil contamination and particulate accumulation challenge reader durability.

Solutions:

1. For barcode occlusion caused by water droplets on crankshaft surfaces or barcodes engraved on curved surfaces, the code reader's intelligent AI decoding algorithm can provide a solution. The AI decoding algorithm can recognize and read barcodes that are skewed, distorted, obscured, or damaged.

2.To address the issue of surface reflections on metal crankshafts that cannot be eliminated by polarizing filters, we recommend using the R-6000 series code reader paired with a high-resolution camera. It features autofocus capability, a large field of view, and wide applicability. The code reader supports light source adjustment function, allowing selection of appropriate lighting settings based on on-site illumination conditions.

3.The entire series of code readers have an IP65 reliability rating, ensuring protection against dust, oil contamination, and other external factors in the production environment.

Solution Advantages:

A single code reader at a single workstation is sufficient to achieve the solution, reducing labor requirements and improving production efficiency.

The R-6000 series code reader features a compact design and can be easily mounted using L-shaped brackets.