Most manufacturing enterprises opt for machine vision technology or fixed-mount barcode readers to automatically capture barcode data. A typical application is in automotive manufacturing, where fixed-mount readers simultaneously scan QR codes on engine units and identify corresponding pallet barcodes. This enables automatic product-to-pallet association, with all data uploaded to the MES system for full traceability.

Achieve barcode scanning and information binding enabling data upload to MES and information traceability

Barcode Reading Challenges:

1. Battery modules employ laser-engraved (DPM) codes, which increase recognition difficulty.

2. Insufficient laser power during engraving may result in reduced contrast between codes and substrate.

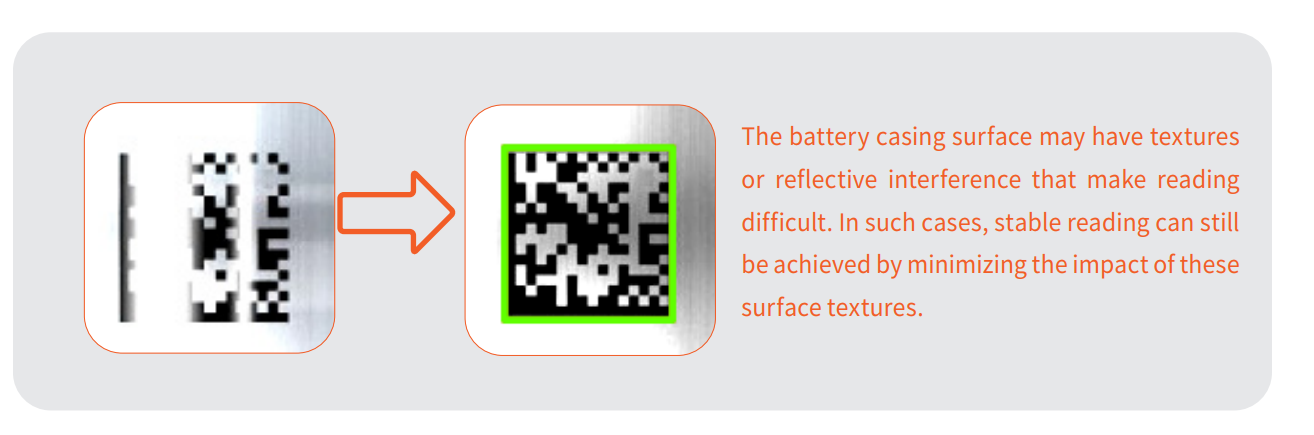

3. Metal surface textures may cause uneven imaging or glare issues.

Solutions:

1.The key challenge in reading laser-etched codes lies in their low-quality QR code markings. For such codes, intelligent AI decoding algorithms can be employed to analyze and read them. During operation, the reader's algorithm performs preprocessing steps including: noise reduction, contrast enhancement, and brightness adjustment to ensure accurate code recognition.

2.For metallic surfaces that may have textures causing uneven imaging or glare. Since it is a metal surface, polarizing filters cannot be used to eliminate reflected light, requiring the combined use of external lighting and the code reader's light source. Both the R-6000 series and R-3000 series code readers feature adjustable focus and independently controlled lighting. The R-6000 series code reader has a larger field of view and higher pixel resolution, making it more advantageous for batch reading. If the production environment is highly variable, using multiple R-3000 series code readers is undoubtedly the better choice. Their networking capability allows flexible installation according to requirements, offering strong adaptability and good cost-effectiveness.