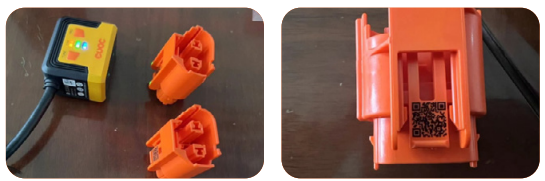

Currently, most enterprises opt for machine vision technology or fixed-mount barcode readers to automatically capture barcode information. Relying solely on manual handheld scanning would impose significant workload, forcing companies to incur high labor costs while being prone to errors. As shown in the right figure, automotive manufacturers typically use fixed-mount barcode readers to automatically scan QR codes on products for managing loading/unloading, station transitions, and inspections. This approach not only operates at high speed to greatly improve efficiency, but also reduces labor costs.

Barcode reading requirements across production processes including loading/unloading station transitions and inspections meeting enterprise needs for improved operational efficiency and reduced labor costs.

Barcode Reading Challenges:

Barcode Reading Challenges:

1. Orange plastic workpieces (color-approximating red) may cause imaging difficulties with the reader's native red lighting, potentially affecting barcode acquisition;

2. Low-resolution codes with suboptimal spray-marking quality and minor damage significantly increase reading difficulty;

3. Ambient light interference results in QR code shadow occlusion.

Solutions:

1. Regarding the issue of workpiece color being similar to the reader's light source: in actual production environments using red-light readers, orange connectors appear lighter in captured images but this minimally impacts decoding performance. The key requirement is ensuring barcode/QR code markings contrast sufficiently with the background. The R-2000 series fixed-focus reader delivers clear imaging at fixed working distances and fields of view, offering optimal cost-performance for such confined FOV applications with consistent working distances.

2.For QR code shadow occlusion caused by ambient light interference, Evoc Reader allows flexible light source adjustments to eliminate environmental light interference during decoding.