"New employees take too long to get up to speed, dragging down the entire production line's efficiency!"

"Product updates are too frequent—setting up new inspection models takes forever!"

With constant complaints from staff and stagnant production efficiency, the boss finally made a decisive move: "Enough! Time for an upgrade!"

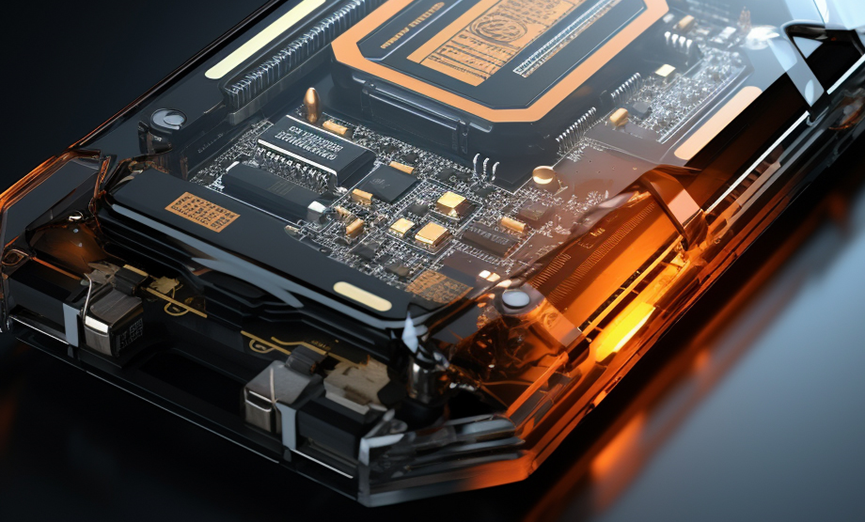

A new batch of in-display AOI inspection equipment was deployed on the production line. How did it perform? Here’s frontline feedback:

Employee A: "We had a new hire earlier who missed screws multiple times—no wonder today’s output fell short."

On complex production lines like TV assembly, new employees often struggle with missed screws, unapplied tape, or unsecured clips, slowing down the entire line.

Enter the RegemMarr In-Display AOI Inspection Equipment, featuring an innovative continuous error function. If the same issue recurs—like improperly installed FPC connectors on TVs 1, 2, and 3—the system triggers consecutive alarms, prompting manual checks and guiding operators to verify prior assembly steps.

Employee B: "Another product update—time to set up a new inspection template. I’ll rush to do it during the line stop and pray I can clock out early."

With accelerating product iterations, defining inspection areas (templates) for different models is critical for AOI but often becomes a bottleneck, delaying deployment and disrupting production rhythms.

The RegemMarr In-Display AOI Inspection Equipment revolutionizes this with its "One-Click Auto-Modeling" feature. It automatically detects regions like screws, clips, and tape from reference images, requiring only minor manual adjustments—slashing setup time and supercharging efficiency!

What began as a gripe session turned into a rave review! The RegemMarr ET-5000 tackles every production line’s efficiency challenges head-on!