Introduction: In semiconductor manufacturing, tiny chips the size of a fingernail are laser-marked with micron-sized QR codes. After undergoing 300°C reflow soldering, these critical traceability codes may become blurred or deformed—yet the production line keeps moving at high speed. Traditional barcode readers often fail in such scenarios.

This is a lesser-known but vital battleground in the rise of domestic semiconductors: high-precision industrial code reading.

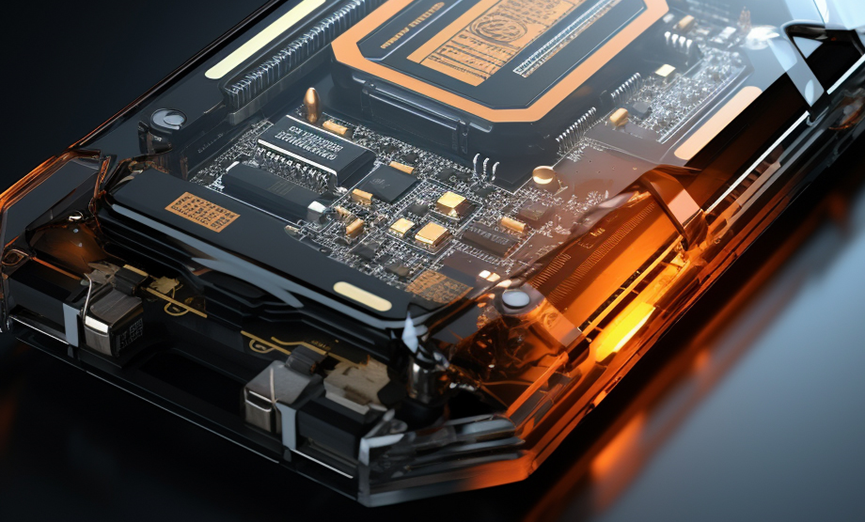

As the semiconductor industry advances, most production facilities require traceability through barcode reading across processes like PCB assembly. Machine vision inspection paired with barcode scanning has become essential. Regem Marr, the "Barcode Reading Expert," offers the AI-powered R-6000 series smart barcode reader to semiconductor manufacturers. With three key technological breakthroughs, it enables intelligent and digital management at the production source.

1. High Accuracy: AI Decoding Rate of 99.99%

Equipped with a megapixel sensor and mil-level (1/1000 inch) precision hardware, combined with a deep learning algorithm trained on 2 million datasets, the R-6000 can pinpoint DPM (Direct Part Marking) codes as small as 0.1mm² on wafers—like "finding a needle in a haystack." Its proprietary 2D Ultra positioning technology penetrates dirt, low contrast, and even partially damaged codes, achieving a 99.99% read rate.

2. High Speed: Millisecond Dynamic Response

Featuring an auto-focus lens and a dedicated NPU acceleration unit, the R-6000 completes decoding in milliseconds, keeping up with production lines moving at 5m/s. Its innovative "Speed-Balance-Enhance" triple-mode decoding strategy intelligently adapts to line rhythms, eliminating bottlenecks.

3. High Reliability: Military-Grade Durability

Tested for vibration, extreme temperatures, and electromagnetic compatibility, with an IP65 rating, the R-6000’s sealed anti-corrosion design withstands chemical exposure in semiconductor cleanrooms. Its operational lifespan exceeds 40,000 hours—far surpassing industry standards.

These capabilities make the Regem Marr R-6000 series the core "sentry" for end-to-end semiconductor traceability—from wafer intake to chip packaging and PCB assembly—building a complete digital twin chain.

Application Scenarios: Tackling Semiconductor Manufacturing’s Three Battlefields

The Miniature Battlefield:

Wafer QR codes are typically smaller than 2×2mm, challenging for traditional readers. The R-6060H achieves non-contact micro-code recognition, eliminating contamination risks.

The High-Temperature Battlefield:

Post-reflow soldering, PCB codes often blur or deform. In factory tests, the R-6060H maintained a 99.98% read rate under residual heat, solving the industry’s "high-temperature code loss" problem.

The High-Speed Battlefield:

At 3m/s line speeds, traditional readers miss codes. The R-6060H’s auto-focus lens and deep learning algorithm deliver faster, more reliable decoding for high-speed semiconductor lines.

Currently, the Regem Marr R-6000 series is deployed across semiconductor production—wafer cassette ID recognition, die bonding, post-molding batch tracing, and finished product verification. With its AI-powered decoding, industrial robustness, and scenario-specific adaptability, it is reshaping semiconductor traceability systems, boosting efficiency, cutting costs, and accelerating the adoption of domestic semiconductor equipment!