National Subsidy" Big Discounts—Have You Upgraded Your Electronics Yet?

As production processes and sales scales of 3C electronic products (such as smartphones and computers) continue to expand, challenges in barcode reading have become increasingly prominent:

Low-Contrast Codes on Hard Surfaces: Marks directly engraved (via laser etching, dot peening, inkjet printing, etc.) on metal, plastic, ceramic, or glass surfaces often suffer from poor contrast and interference from substrate textures and glare.

Deformation Due to Folding: Creases or folds can distort or partially obscure barcodes, compromising decoding accuracy.

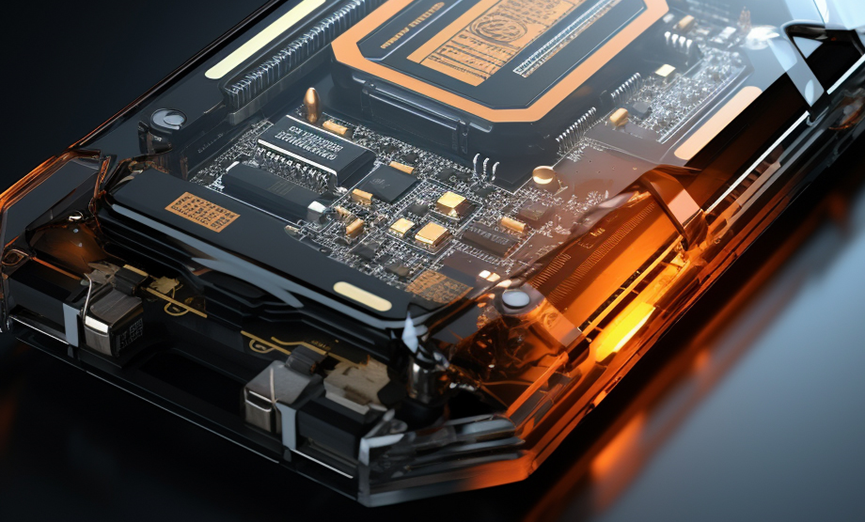

Tiny DPM Codes on Components: Direct Part Marking (DPM) codes on miniature 3C parts (e.g., resistors, capacitors, and IC chips on PCBs) demand extremely high precision in both marking and scanning equipment.

Can You Decode 10 Codes at Once?

Currently, Regem Marr Xiamen Rearch Goldcode's intelligent barcode readers are widely adopted across the 3C electronics industry, covering product assembly, quality inspection, and process control. The integration of "AI + Manufacturing" is empowering more enterprises with efficient, accurate, and traceable production management solutions.