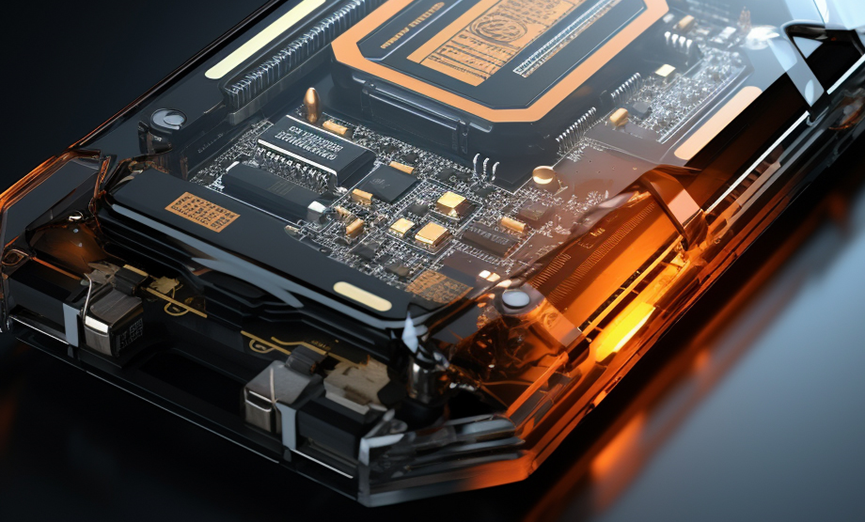

Smartphone PCBs: The Critical Hub Demanding Precision Traceability

As the central nervous system of mobile devices, smartphone PCBs require rigorous quality traceability to ensure optimal device performance and consumer protection. Each laser-marked QR code serves as the PCB's unique "quality passport," encoding its complete production history.

QR Code Reading Challenges in PCB Manufacturing:

Post-Reflow Complications: QR codes often become blurred or lose contrast after solder reflow processes.

Micro-Scale Density: Requires simultaneous rapid reading of multiple miniature QR codes.

Zero-Tolerance Accuracy: Production demands near 100% data capture accuracy with no margin for error.

High-Efficiency Precision Decoding Solutions

Regem Marr Xiamen Rearch Goldcode's intelligent decoding technology provides reliable solutions:

Superior Micro-Code Reading:

The compact R-6000H series features flexible installation and AI-powered algorithms optimized for sub-millimeter codes

Maintains stable reading even with low-resolution or distant QR codes

Advanced Complex Code Recognition:

Combines AI with 2D Ultra positioning technology to handle damaged, blurred, or distorted codes

Ensures >99.9% decoding accuracy in challenging conditions

High-Speed Dynamic Reading:

Supports reading at 1m/s movement speeds

Multiple triggering modes (software/external/continuous) adapt to various production line rhythms

Provides technical assurance for 100% data accuracy

Recommended Model & Application: R-6060H

Implementation: Mount the R-6060H above conveyor belts at PCB "identification stations." When boards reach the checkpoint, the reader instantly captures QR code data, which is:

Automatically bound to station operation records

Uploaded to MES systems in real-time

Creates complete traceability from individual boards to entire batches

Value Proposition: This solution guarantees complete and accurate production data collection, establishing a robust foundation for:

Quality traceability

Process optimization

Defect analysis

Ultimately protecting both manufacturer interests and end-user rights.