The transformation from traditional automobiles to intelligent electric vehicles requires undergoing the "New Four Modernizations" revolution: electrification, intelligence, connectivity, and sharing. These "New Four Modernizations" also impose higher demands on automotive chips themselves. For example, main control chips require higher computing power, while power devices and MCUs need lower power consumption and higher reliability. To meet these requirements, advanced packaging technologies are becoming the mainstream choice for automotive chips. After packaging is completed, it is necessary to bind the work instruction codes with the current product to facilitate backend queries about which operations were performed on the product and when it passed through stations.

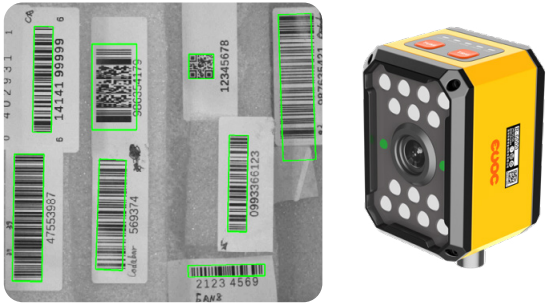

Achieve barcode reading recording and traceability for advanced packaging products

Barcode Reading Challenges:

1. Multi-code reading with varying sizes.

2. Ambient light causing label glare.

3. Label codes susceptible to damage and contamination.

The combination of inconsistent label sizes, variable barcode quantities, and issues like glare, wrinkles, and dirt on labels significantly increases decoding difficulty.

Solution Advantages:

For the challenge of simultaneously reading multiple codes of varying sizes, the key difficulty lies in decoding small edge-positioned barcodes. The primary solution is to use large field-of-view (FOV) readers with uniform illumination to ensure overall image clarity. The R-6000 series performs exceptionally well in such production scenarios, with its matrix lighting design guaranteeing illumination uniformity across wide areas. Furthermore, the R-6000 series employs high-resolution cameras with outstanding small-code decoding capability in large FOVs, enabling rapid localization and reading of small codes distributed at the edges of the reader's FOV. Its auto-focus function also simplifies installation and debugging.

Solution Performance:

1. Achieves 98.3% read rate for damaged/contaminated codes with <20ms decoding time.

2. The R-6000 series demonstrates superior depth-of-field performance, delivering excellent reading results for tilted codes and non-coplanar codes.